HARBEC has researched and developed a plan that would help the company become more efficient and more ecologically correct. A significant part of the solution is called cogeneration, a highly efficient means of generating heat and electric power simultaneously from the same energy source. In other words, the exhaust heat from generating electricity replaces fossil fuel (oil, coal, or natural gas) combustion. This is the heat that would normally be discharged into lakes and rivers or the atmosphere in the current process of traditional utility power generation.

Efficient Energy Usage Through Cogeneration

The co-generation process produces both electricity and heat (hot water or steam) at the same time. It is much more efficient than a single-purpose generating system because it extracts much more usable energy from the same fuel. In the most common form of utility type electric generation, fossil fuels are burned in a boiler to heat water. The steam produced by this process drives a turbine attached to an electric generator, which converts this energy into electricity. The excess heat is usually released into the atmosphere via stacks or cooling towers, or into a river or lake. As a result, most of the energy contained in the fuel source is wasted. With co-generation, the excess heat is captured for use in an existing heating and cooling system. The overall efficiency improves when the thermal energy from the exhaust is used to heat and cool buildings. This heat or thermal potential can also be used as process heat when needed in manufacturing, which will increase fuel use efficiency even more.

CHP represents an opportunity to make significant progress toward meeting our Kyoto commitments on greenhouse gas reductions. The local air quality improvement and opportunities for economic growth presented by CHP are equally compelling. CHP presents an opportunity to improve the “bottom line” for businesses and public organizations, while also providing a path for improving the environment. HARBEC believes the private sector should actively pursue adoption of CHP—both for “bottom-line” economic and environmental benefits.

HARBEC regards sustainability as absolutely critical to the future of our business, and we believe that our success in the pursuit of it, will improve our competitive advantage by ensuring our efficiency. Sustainability can be a cost-effective opportunity for business today which ensures a viable and comparable world to live in for future generations.

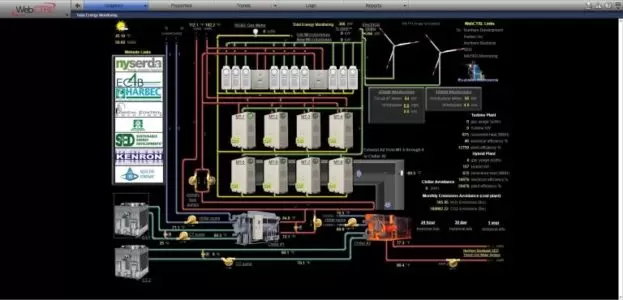

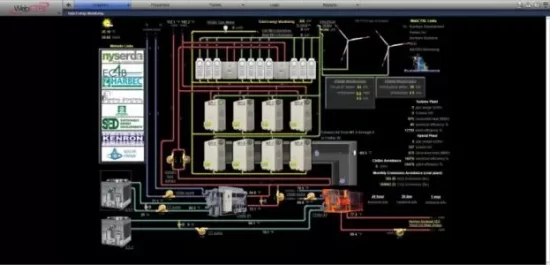

If you are interested in viewing our up to the minute energy data, please follow this link:

https://webcontrol.harbec.com/

Note: When you are at the login page please type “guest” in the Name box; no password is required. Then just press the “log in” button.

The Future

Co-generation or Combined Heat and Power can contribute to the transformation of the United States energy future. CHP offers significant economic advantages for energy efficiency improvement and emissions reductions. Our existing system of centralized electricity generation charts an unsustainable energy path with increasing fuel consumption and carbon emissions while continuing to squander over two-thirds of the energy contained in the fuel. At least half of this wasted energy could be recaptured if we shift from centralized generation to distributed systems that co-generate power and thermal energy. CHP represents an opportunity to make significant progress toward meeting the Kyoto guidelines on greenhouse gas reductions. The local air quality improvements and the opportunities for economic growths presented by CHP are equally compelling. CHP presents an opportunity to improve the “bottom line” for businesses and public organizations, while also providing a path for improving the environment. The primary barriers to greater CHP use are regulatory and institutional, not technical or economic. The private sector must work with government regulators and policymakers to ensure that competition and incentives for innovation are preserved while creating a favorable regulatory environment for CHP and Distributed Generation (DG). HARBEC believes the private sector should actively pursue adoption of CHP -both for “bottom-line” economic and for environmental benefits.

CHP Project application features:

- 17,000′ of 1″ Diameter tubing for radiant floor heating

- Air-to-water heat exchanger delivers hot and cold water to the rest of the building’s HVAC system and uses high-efficiency Air Sox to deliver conditioned air.

- Computer controlled sensing and delivery system

- 5 Heat exchangers 1 unit per four microturbines used to extract heat (thermal energy) from the exhaust gas and put it into the water for heating and air-conditioning requirements

- 1 Absorptive Chiller Converts 210° water to 44°-47° water for use in air-conditioning with no additional fuel costs